Doping - Spin-On-Dopant synthesis

We propose two ways for obtaining phosphorus based SOD.#1

Butanol + phosphoric acid - 16:1 volume ratio.

Process:

- RCA clean of the wafer.

-

Hold wafer at the butane flame for approx. 20 seconds until it starts glowing red.

This improves adhesion of the SOD to the wafer. - Spin coat at 3000 RPM, 20 seconds.

- Predeposition on hotplate 165°C, 90 seconds.

- Thermal diffusion @ 930°C, wet 15 minutes, dry 45 minutes.

- Oxide etch in HF bath.

Disadvantages include relatively poor adhesion to the wafer (which is offset by holding above the butane flame).

Non-uniform coverage of the wafer when spin coating, resulting in visible openings in the predeposited material.

Requires additional double-oxidation step to promote better PSG formation and lift-off.

#2

Base: TEOS + EtOH + Water - 3:24:3 by mass

SOD: Base + phosphoric acid - 1:2 TEOS:H3PO4 by mass.

Slight modification to the synthesis, but rest of the process as in Fangsuwannarak et al. 2019.

Project wiki article for more information.

Process:

- RCA clean of the wafer.

- Spin coat at 3000 RPM, 10 seconds.

- Predeposition on hotplate 200°C, 30 minutes.

- Thermal diffusion @ 1000°C, dry 30 minutes (or more, depends on the device type).

- Oxide etch in HF bath.

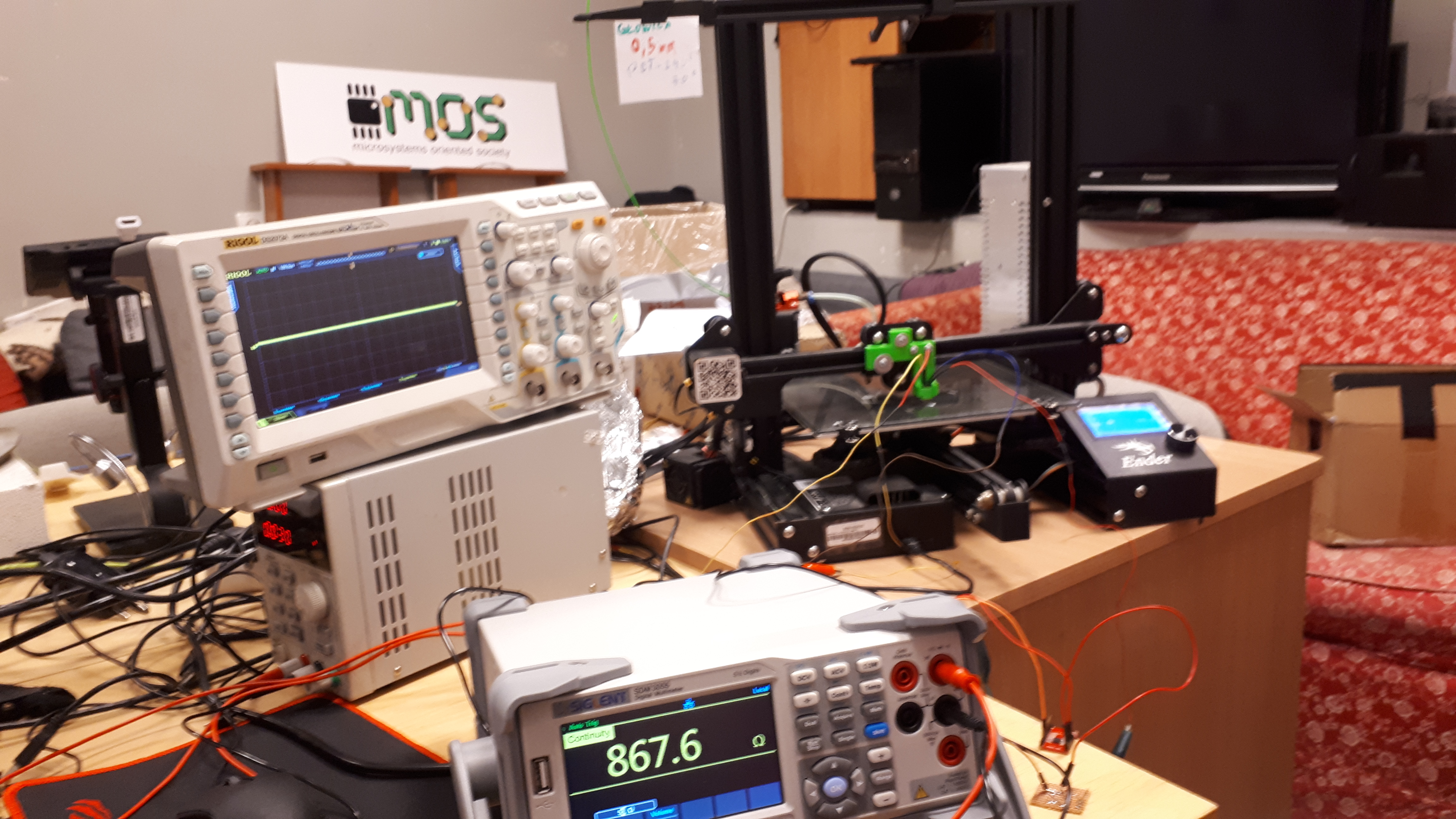

Four point probe testing

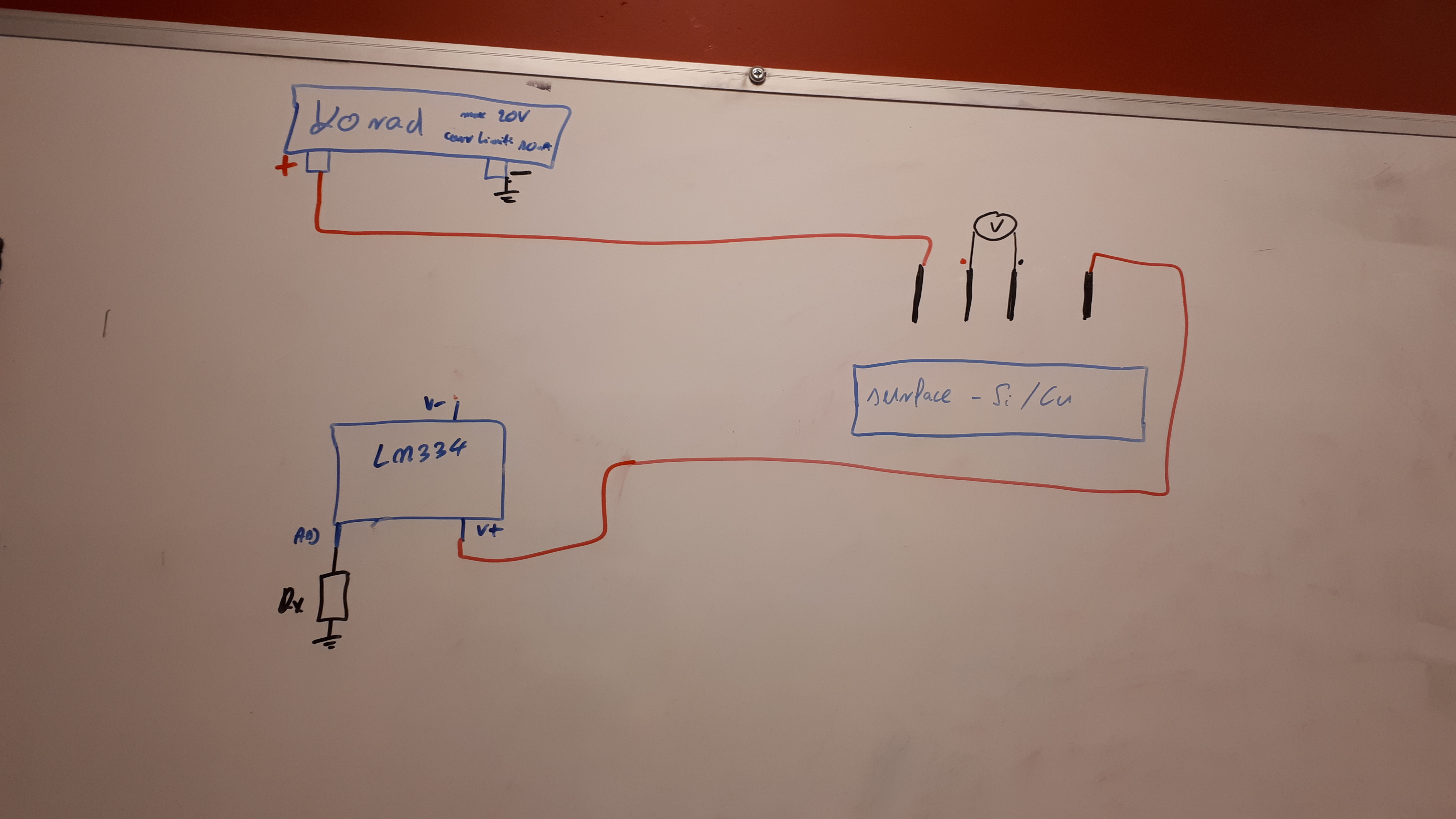

Solar cell testing

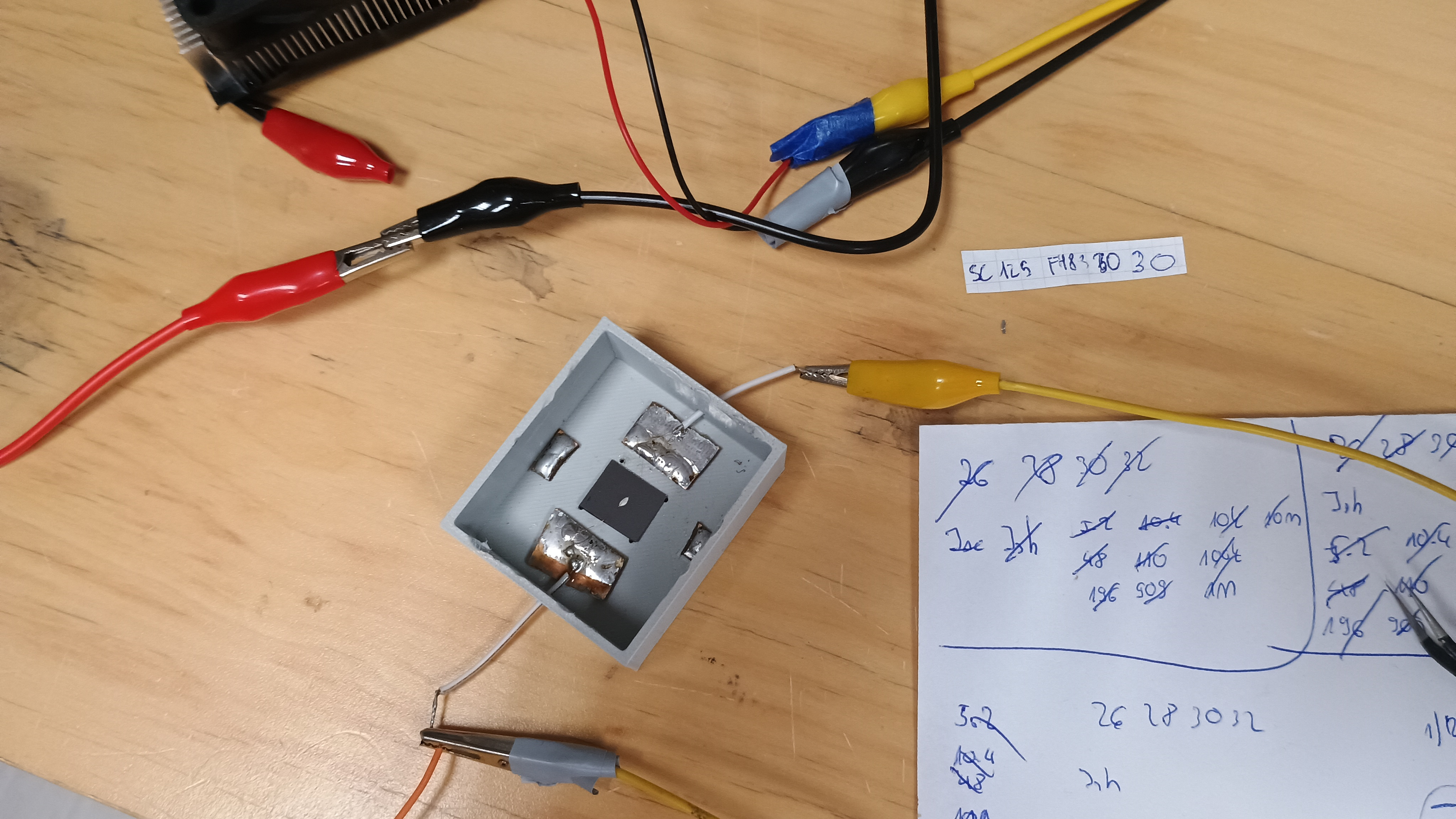

Doping using butanon + phosphoric acid based SOD

Looks ugly, but it may work for some big devices. TEOS based SOD works much better.

High temperature furnace

Hotplate

Metallisation

Photolitography

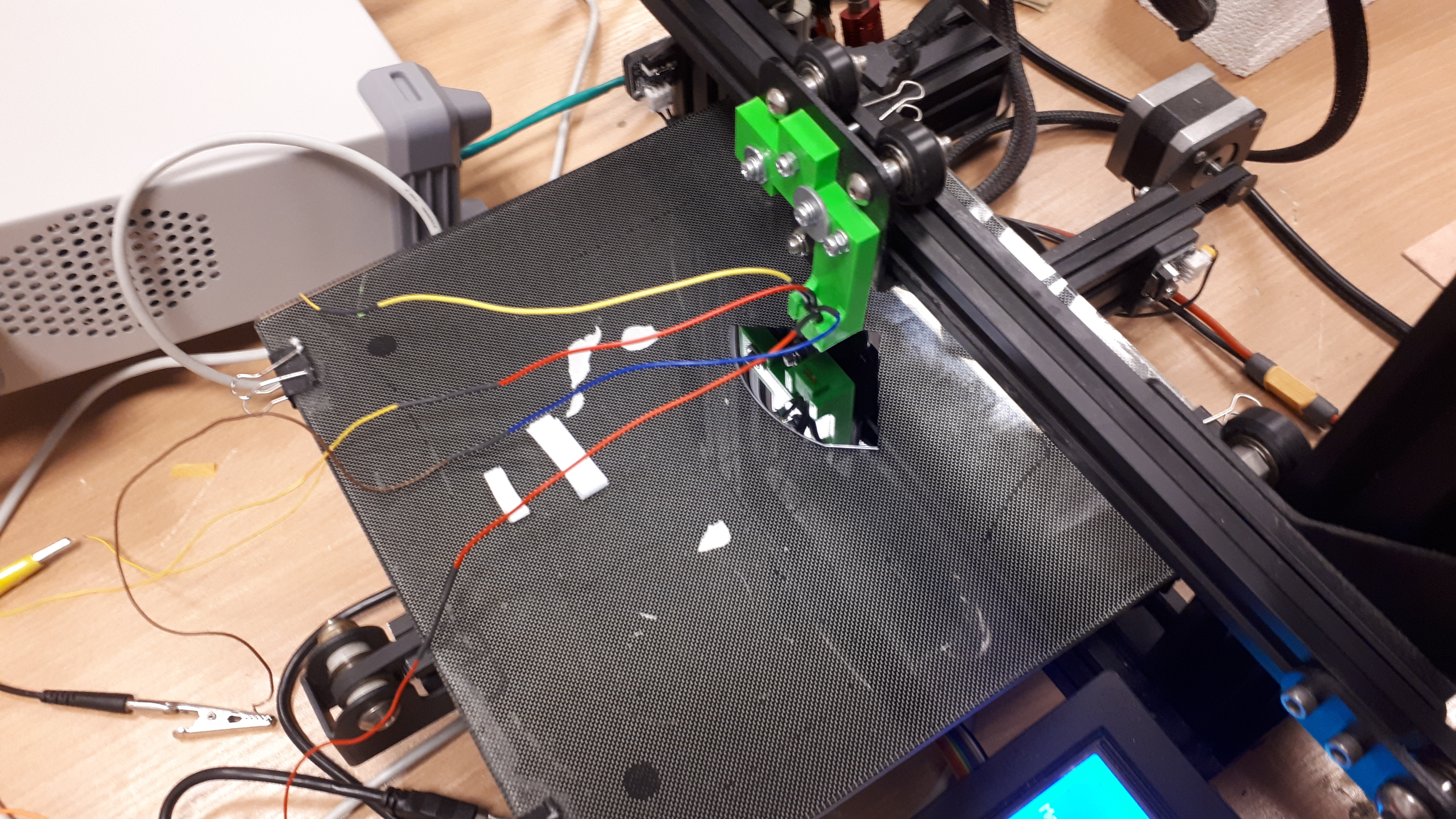

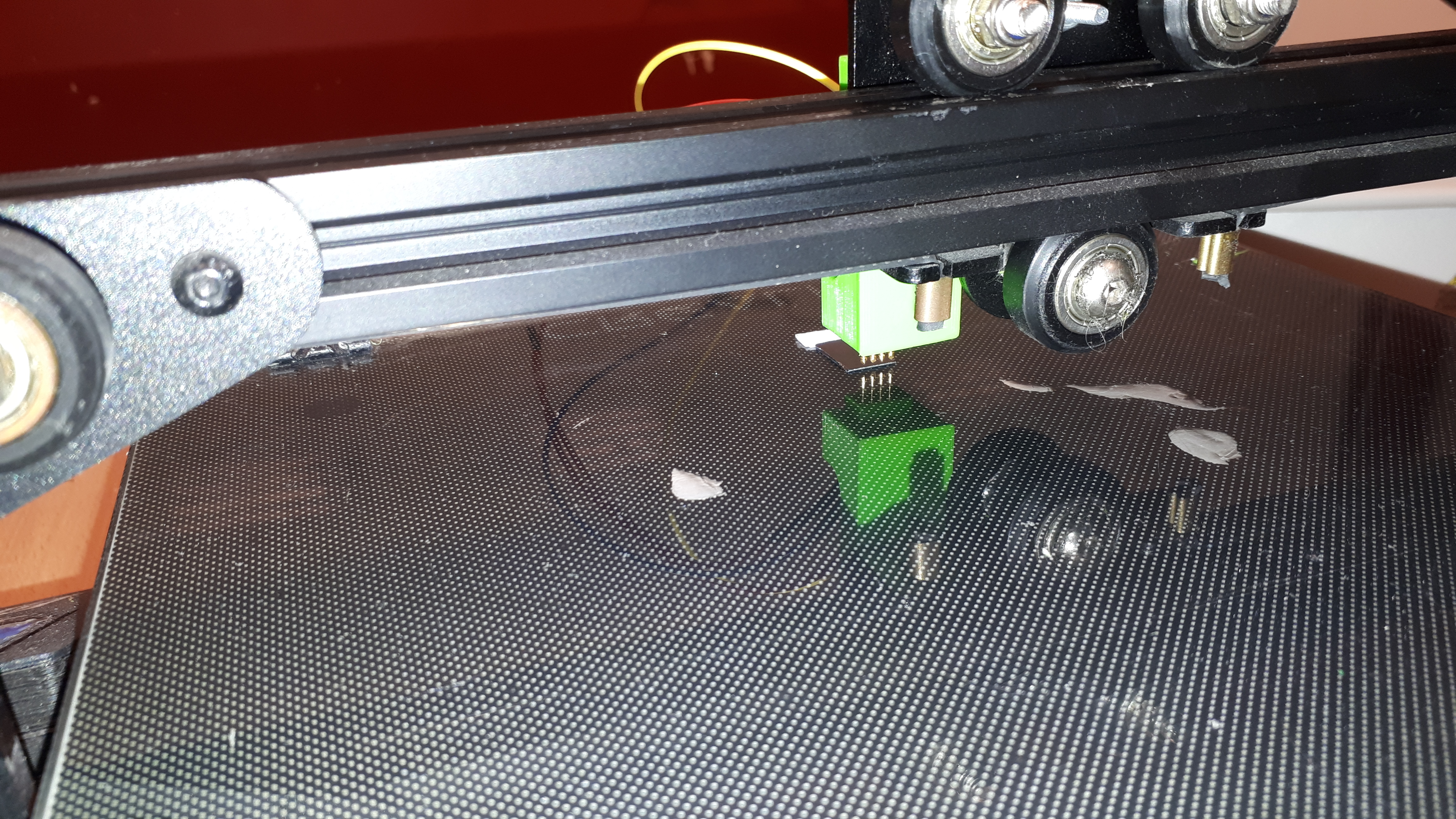

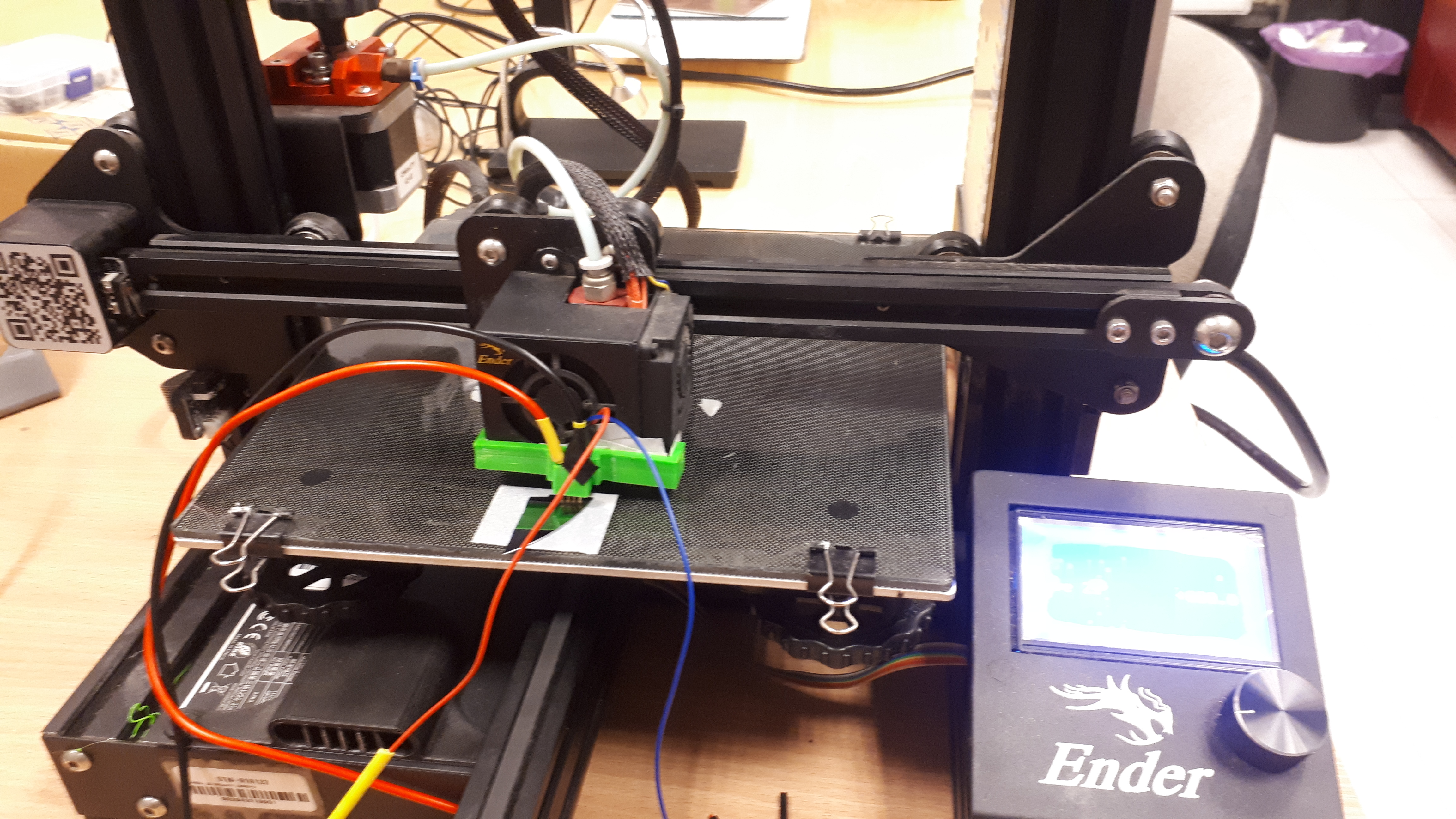

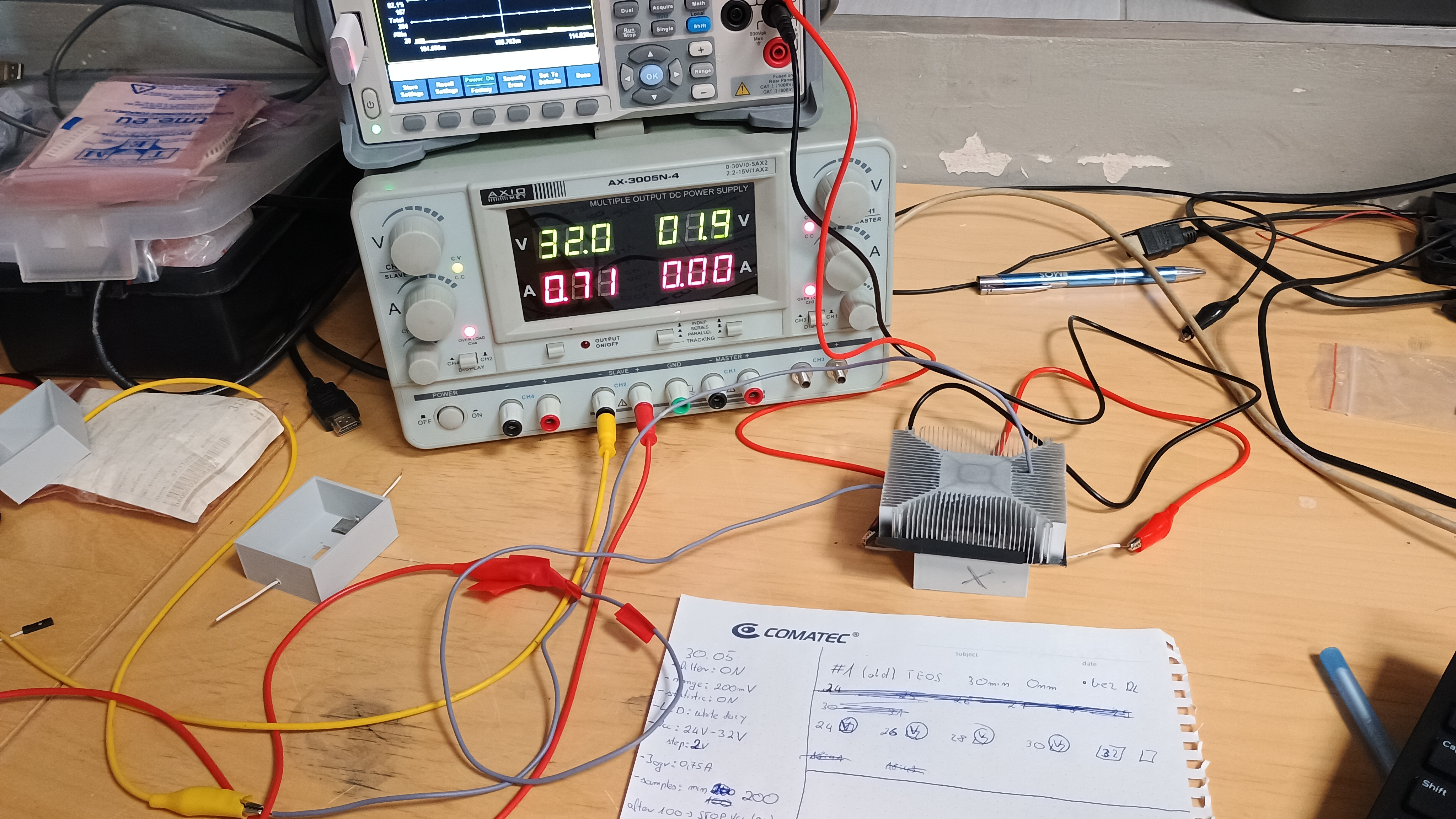

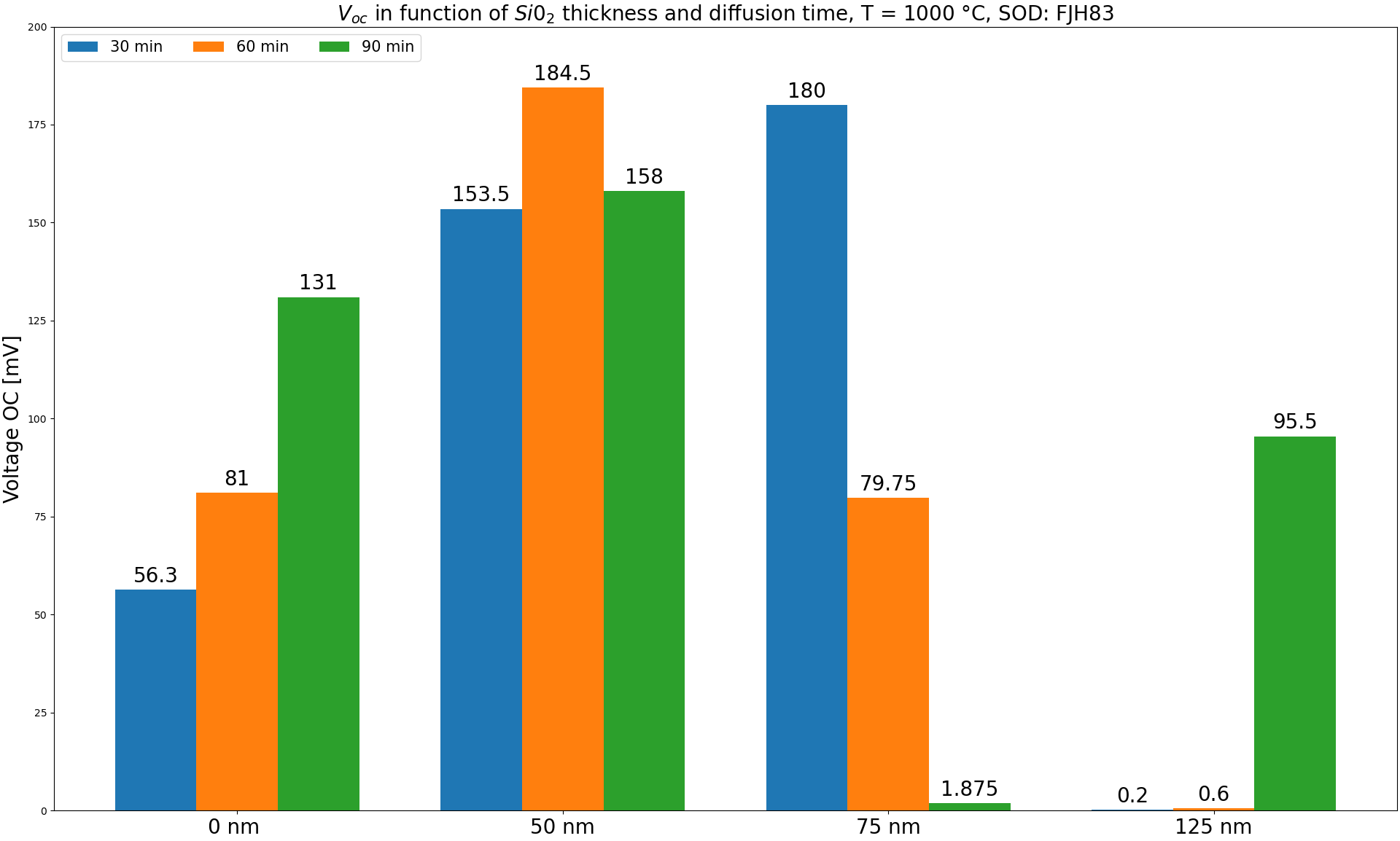

Doping using Fangsuwannarak et Al. 2019 TEOS based SOD.

We tried to control the strength of doping, using thickness of the oxide and diffusion duration.

This doesn't really work that great - we suspect it's because of the quality of the oxide grown.

Higher quality of oxide formation is still a work-in-progress - we are aware of the problems and are addresing them.

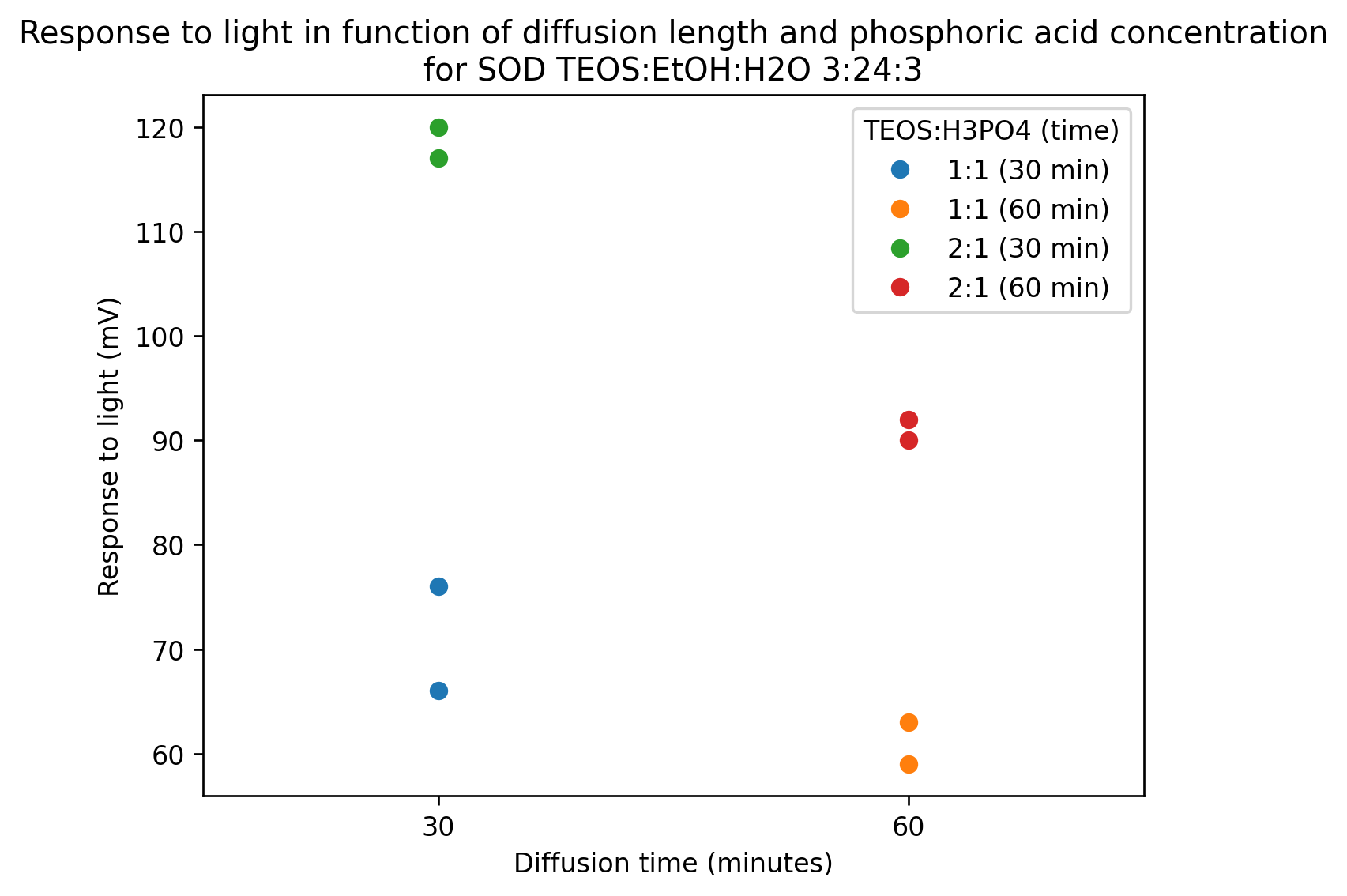

Doping using our TEOS based SOD

TEOS based SOD with variable concentration of phosphoric acid results

does show much better numbers in terms of characterstic of doping.